ENVE engineers utilized proven core technologies to develop the Foundation collection. With ENVE ride quality tuning, tubeless compatibility, and Hookless beads for improved pinch-flat protection, the ENVE Foundation lineup is ready for wherever you want to ride.

Foundation rims are part of the all-function, easy-on-the-wallet, US-made Collection, with profiles available for road and off-road disciplines.

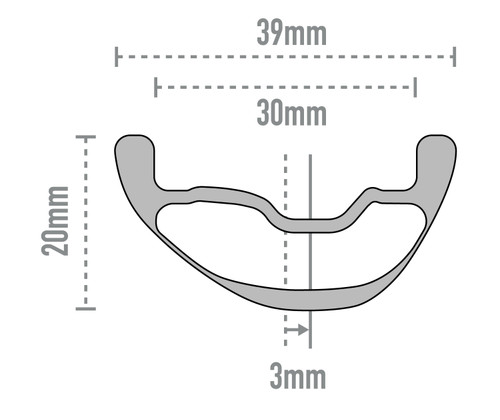

All Foundation rims feature ENVE Wide Hookless Bead technology for anti-pinch flat performance, and to complement higher volume tubeless road tires. ENVE Wide Hookless shapes allows a larger range of tubeless road tires.

The benefits of road tubeless are:

• Lower rolling resistance – By eliminating the inner-tube, the friction between tire and tube is also eliminated, allowing the tire roll, flex, and conform to the road with greater efficiency.

• Flat less, ride more – Flat tires are a buzz-kill. With a little sealant you can eliminate nearly all flats that would have been caused by an intrusive thorn or piece of debris.

• Run the Best Pressure – Tubeless means you can run the pressure you want to maximize comfort, traction, and rolling efficiency. (Visit the ENVE tire pressure page to dial in your best tire pressure)

• Hookless/Straight-Sidewall Design -Tubeless performance depends on the tire maintaining a light press-fit with the rim on the bead seat diameter. ENVE chooses a hookless tubeless rim profile as it allows the rim’s critical tolerance at the bead seat diameter to be both consistent and accurate. In short, hookless is chosen to deliver a more safe, reliable, and ultimately proper tire fitment.

Wheelbuilder Custom: We understand the online selection process can be challenging. Our custom wheel pages were developed with intelligent filters that reduce the seemingly endless number of hub combinations to those that apply to you. Plug in your basic axle, frame and drivetrain requirements within any of our custom wheel pages, and let our smart filters show you the possibilities. We invite you to take a journey exploring the range of hub options available for your next custom build.

Not sure what to choose? Call (626-442-4444) or email us. Our expert sales staff are always happy to discuss component options and make recommendations for optimal performance.

IMPORTANT: Base package includes ENVE Foundation Carbon rim, ENVE Foundation Alloy Road Centerlock disc hub, black heavy duty bladed aero spokes, ENVE brass nipples, tubeless rim tape, tubeless valve stem and labor.

Technical Information:

- Hub Offerings: Select your Rim, Axle, Drivetrain, and color preferences from the drop down menus then allow our smart filters to sort compatible hubs for your application. For more detailed information on any of our road disc or gravel hub offerings please visit our Road Disc Hub Category.

- Spokes: Wheelbuilder caries a wide range of high quality spokes from leading manufacturers. We select the exact spoke model and manufacturer based on a combination of your selected spoke type as well as hub flange thickness and spoke hole diameters. If you have a specific brand preference please leave us a note in the comments field.

| Rim (Click for link) | Rim Weight | Rim Profile Height (Fr/Rr) | Rim Width (External/Internal) | Application |

| ENVE 45 | 455g | 45mm | 28mm / 21mm | All-Road, All Purpose, Aero |

| ENVE 65 | 510g | 65mm | 28mm / 21mm | All-Road, All Purpose, Aero |

| AG25 - 700C | 360g | 21mm | 33.5mm / 25mm | Gravel, Adventure, All-Road |

| AG28 - 650B | 372g | 21mm | 36.5mm / 28mm | Gravel, Adventure, Off-Road |

About Our Custom Builds:

All Wheelbuilder custom handbuilt wheels pass through our exacting quality assurance process, which includes full tension analysis with meters designed, built and calibrated in-house. Modern engineering production methods adopted from automotive and aerospace manufacturing are used to guarantee accuracy during each step of our build process. No detail in our assembly or quality assurance process is left to chance. Learn more about the Wheelbuilder Difference.