Build Process/Durability

Wheelbuilder differentiates itself from other custom builders through our precision build process. Our process has evolved through years of comprehensive engineering scrutiny to identify critical stages of production. Multiple quality assurance checkpoints are used to guarantee spoke tension consistency, maximize wheel strength and deliver wheels that stay true for thousands of trouble-free miles.

Bicycle wheels are complex structures subjected to loads that regularly exceed wheel mass by orders of magnitude. Well built wheels can endure more than 30 million load cycles in a working lifespan. Fatigue is by far the primary source of failure, with corrosion and crash damage coming in a distant 2nd and 3rd place. Small details in build process and component selection can dramatically alter the lifespan of a wheel. Having a visually straight wheel means very little, and is not a reliable metric for evaluating the quality of a wheel build. Spokes that are improperly tensioned, for example, will always fail first in high cycle fatigue regardless of how true a wheel is.

The Wheelbuilder process includes rigorous tension control and post stress measurements developed in house with input from leading rim manufacturers. We aim to understand the dynamic characteristics of each material, from alloy to carbon, and even wood, to maximize durability under high cycle fatigue stress. Wheelbuilder internal standards and our approach to wheel construction are truly unique to the craft of custom wheel building. It is our mission to deliver reliable high performance wheels that will remain lively after thousands of miles. We invite you to experience the Wheelbuilder Difference for yourself.

Custom Wheels Fit the Individual

Listening to our customers is the critical first step in the Wheelbuilder process. Each athlete has different needs based on physiology, application, environmental conditions, and budget constraints. We love talking to our customers, and there is no better way to help us understand each athlete. Our expert sales staff will take time to explain the trade-offs of weight, durability and component limitations for each configuration we recommend. Please feel free to contact us for help with your next set of wheels.

Photo: Amber Neben - 2X World TT Champion, Olympian, 2X US National Road Champion, 3X US National TT Champion

Inventory

Wheelbuilder stocks the world's largest specialty inventory of high-end bicycle wheel components. Extensive inventory enables us to custom build unique wheel variations to suit your needs. We maintain strong partnerships with industry leading manufacturers that allow us to offer rims and hubs exclusive to Wheelbuilder. With over 500,000 spokes varying in length, shape, color, wire diameter and attachment type, we are well equipped to deliver the best-optimized configuration for your application. If you are interested in something you don’t see on our website please contact us.

Engineering Expertise

Combining over 30 years of wheel building experience with a strong engineering and manufacturing background provides a rare combination of hands-on proficiency and technical expertise. Wheelbuilder was created and exists to advance the craft and science of wheel building.

Engineering design projects force us to ask challenging questions on how components function. Whether we are designing components for Olympic track sprinters, carbon fiber axles for Tour de France champions or gearbox elements for industry partners, our focus remains on understanding and advancing the state of engineering in cycling.

Putting components together into a finished wheel is not the same as understanding the underlying structural principles that dictate how components will interact. A deeper understanding of how complex combined loads are applied to a wheel is key to wheel performance and survival.

Proven by Champions

Wheelbuilder wheels have been proven by the top tier of cycling elite from track World Champions to podiums at the Tour De France and medals at four Olympic Games. We are proud, and truly honored, to have the opportunity to work with the world’s best athletes and coaches.

Photo: Jamie Staff- 2X World Champion BMX & Kerin, Olympic Gold Medalist / World Record Mens Team Sprint

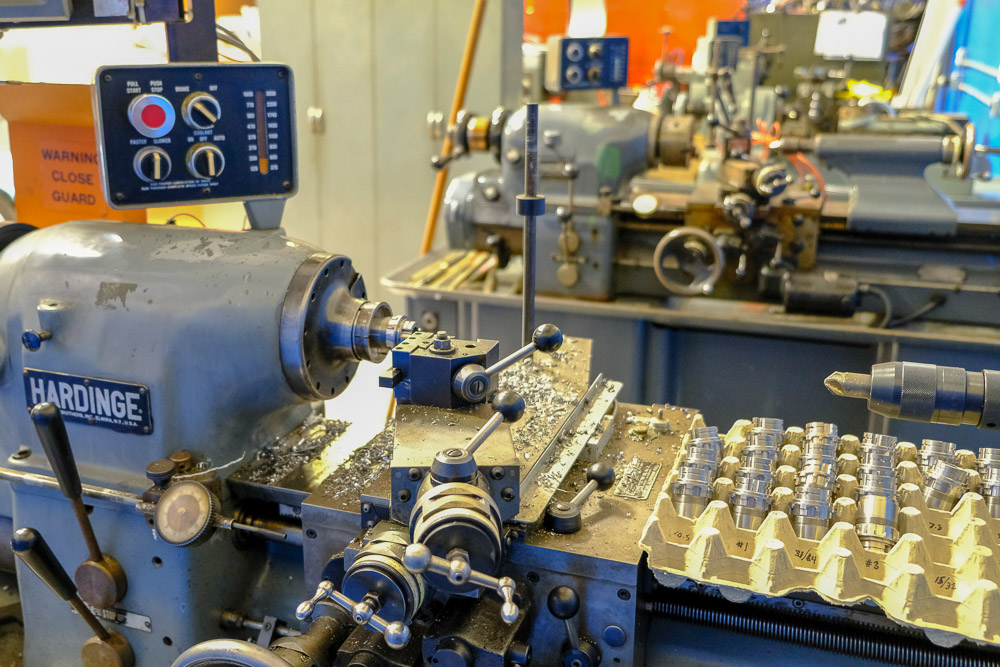

Precision Machine Shop

Wheelbuilder has a full machine shop on premises, allowing us to develop prototypes and manufacture test components. We initiate virtual concepts using advanced computer aided engineering tools for design and analysis. Modern 3D printers and conventional machine tools allow us to control every step of the development process. Everything from customized wheel building tools to carbon fiber axles used at the Tour de France have been designed, tested and manufactured to our exacting specifications.

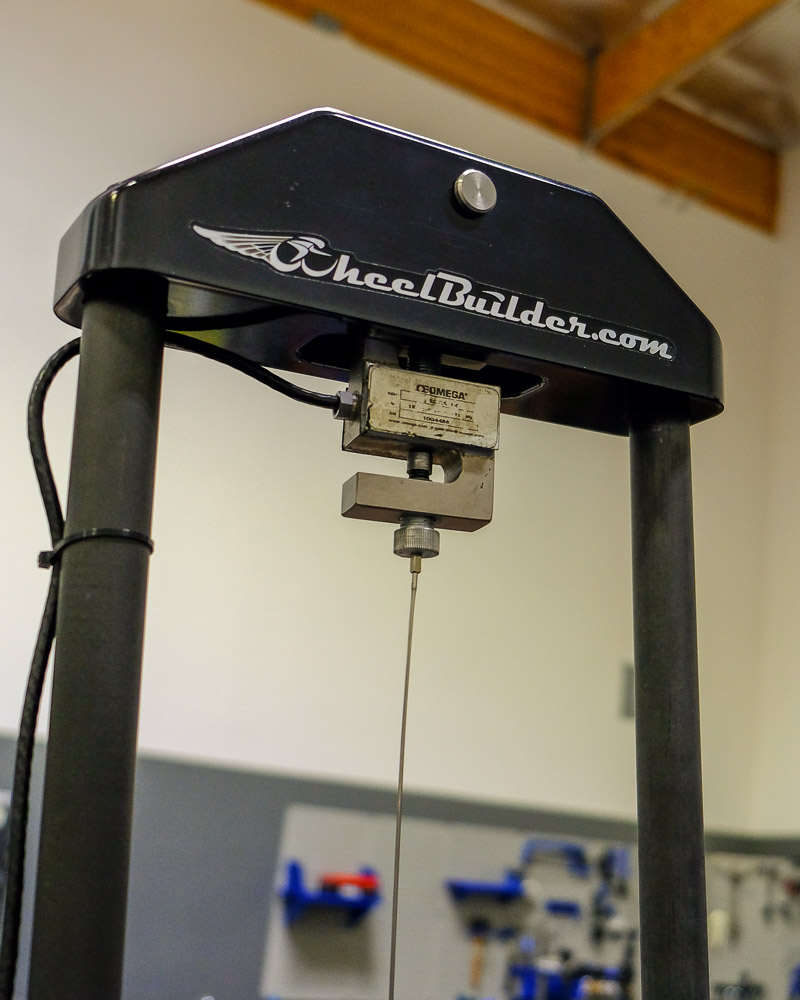

Calibration

Precision builds MUST be accurate and repeatable. Highly specialized measurement devices called tensiometers are used to quantify spoke tension. Unfortunately few meters are calibrated after leaving the factory, which leaves great uncertainty in measured values critical to build quality. We have designed and developed highly accurate calibration tooling, allowing us to examine each tensiometer and maintain accuracy across all of our measurement equipment. We even make machines for commercial use in high accuracy spoke tension calibration for other shops.

Wheelbuilder Culture

Wheelbuilder's work culture values honesty and integrity with extreme pride in craftsmanship. Our workplace is a fun environment with a friendly, dedicated, and proactive staff. Relationships are key to our success and it is our mission to provide you with an excellent customer experience. Thank you for being part of the Wheelbuilder story.