Current stock:

0

Nipple washers are sold in packs of 20 pieces and can be used for three key purposes in wheel building.

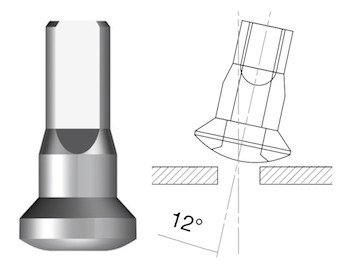

- To increase the load distribution area at the interface between the nipple head and rim nipple bed. Improved load distribution can be critical in thinner walled rims. Washers are often mandatory on some carbon rims to mitigate the effects of interrupted fibers where holes have been drilled.

- To reduce friction between the nipple head and the rim bed.

- To reduce the effects of galvanic corrosion when aluminum nipples are seated against carbon fiber. Carbon fiber is a semi-conductor that will act as the cathode of a battery when in contact with aluminum, making the nipple a sacrificial anode in the presence of moisture. Ocean air with increased salt content will supercharge the process. Washers are a small benefit when used with a dielectric grease.

Nipple washers are sold in packs of 20 and serve three primary functions in wheel building.

- They increase load distribution area between the nipple head and the rim nipple bed, which is particularly important for thin-walled rims. On some carbon rims, washers are required to mitigate stress concentrations caused by interrupted fibers at drilled spoke holes.

- They reduce friction between the nipple head and the rim bed making final tension easier to achieve in high friction applications.

- They also help limit galvanic corrosion when aluminum nipples contact carbon fiber. Carbon fiber can act as a cathode, making aluminum a sacrificial anode in the presence of moisture—an effect accelerated in salt-rich environments. Washers will provide additional protection when used with dielectric grease.

Technical Information:

- Weight: 32 nipples weigh 32g (10mm length); 1g / nipple

- Material: brass

- Color: Silver

- Length: 10mm

- Standard thread gauge: 2.0mm(14g)

- Optional thread gauge: 1.8mm(15g) Please request in comment field.

- Wrench interface: Square drive 3.2mm. Park SW-16 or SW-15

Notes:

- Minimum order quantity is 20 pieces priced per package