Thru Axles Demystified

Thru Axle wheel attachment systems have become common on virtually every type of disc brake application from DH mountain bikes to Road Disc Brake, CX, Gravel, and Touring. Thru Axles provide the key benefits of; increased clamping force, and improved stiffness of frame/fork structures by acting as partial stress members.

While most frame and fork manufactures have adopted common hub width and axle diameter combinations based around generalized cycling disciplines, there has been little consensus on Thru Axle specifications. The lack of Thru Axle standards has created a bit of confusion for end users who need to find replacement axles for their frame or fork. This post is intended to help users identify and measure the parameters required to specify a replacement Thru Axle for any frame or fork.

It is important to note there are Thru Axles specific to particular manufacturers frame or forks that are proprietary and must be replaced with a factory axle. This post will help you establish if you have a common axle type or one that must be replaced by the original manufacturer. There is some acceptable tolerance on the total length of the axle (typically +/- ~2mm), which accounts for measurement error and manufacturing differences.

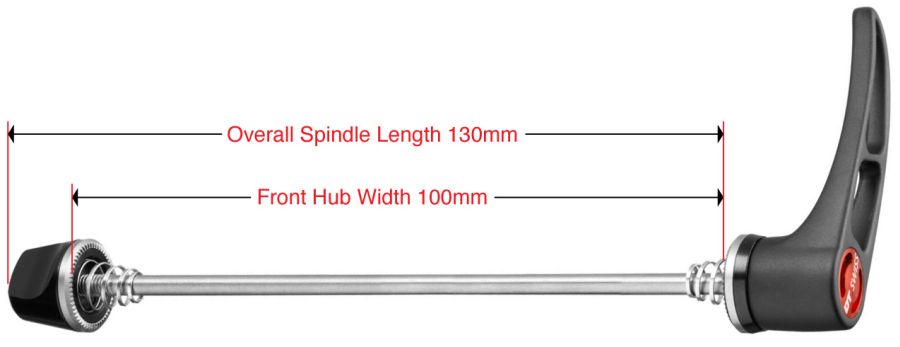

Historically a standard quick release skewer was designed with a 5mm spindle diameter and an overall length equal to the hub width plus enough material to travel through both sides of a frame or fork leaving enough exposed thread to attach a nut. A typical front 100mm QR skewer measures approximately 130mm in total length as detailed in the figure below.

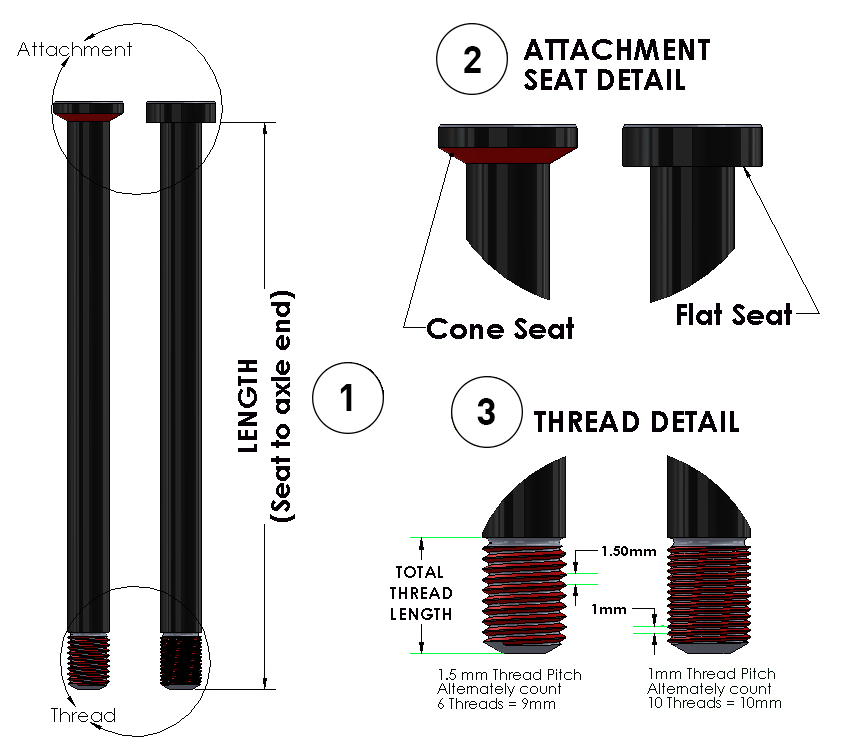

Thru Axle systems follow a similar logic to the basic quick release skewer with three key differences.

- Total length of the Thru Axle can vary dramatically between manufacturers. A "Standard" 142x12mm Thru Axle can vary in length between 162mm and 171mm depending on the frame manufacturer.

- Type of attachment seat used at the interface where the skewer mates to the frame or fork. The two most common attachment seat types are flat (similar to traditional QR), or conical (X-12 type cone seat).

- Thru Axles thread directly into frames/forks which eliminates the need for a nut. This seems like a straightforward concept, however it introduces the question of which thread pitch and how much total thread length to use.

The diagrams below graphically describe the three parameters outlined above allowing you to easily specify the correct Thru Axle for your frame or fork.

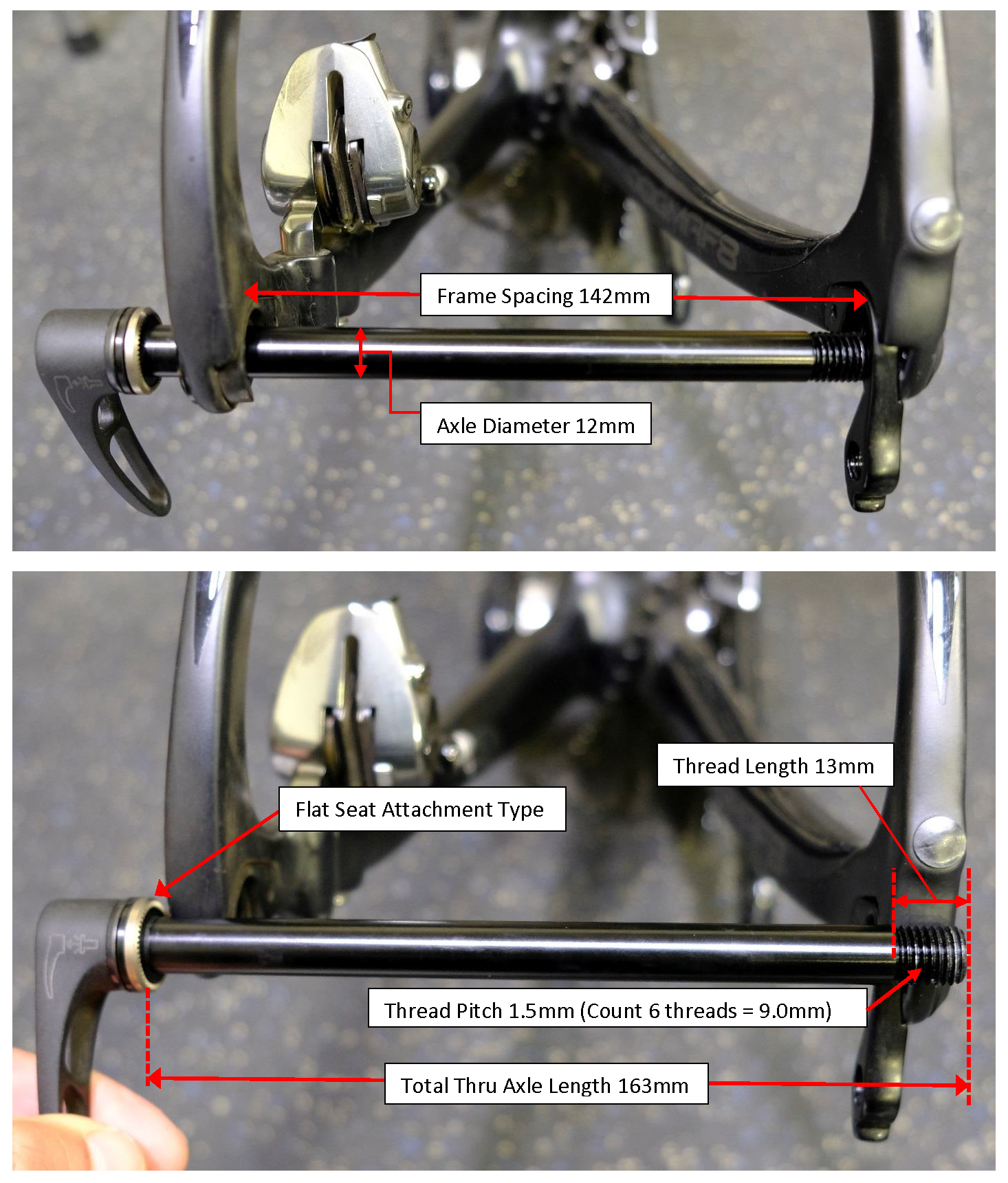

Example of how to measure Thru Axle specifications.

The frame shown below is a road disc model that uses a 142x12mm hub specification. From this specification we know 142mm is the hub width (or frame spacing) and 12mm is the diameter of the axle. We need to specify the following items to get the proper replacement Thru Axle.

- Total Thru Axle length from the seat to the end of the threads.

- The seat type flat or cone shaped

- Thread pitch or (distance between threads) and total thread length

The lower picture indicates all information required to specify a replacement axle

The lower picture indicates all information required to specify a replacement axle

- Total Thru Axle length = 163mm

- Seat type is Flat (as opposed to cone shaped)

- Thread length is 13mm and Thread Pitch is 1.5mm. It can be difficult to measure the distance between threads by eye or with a small ruler. It is easier to simply count 6 threads (at 1.5mm between threads) for a total length of 9.0mm. If the Thread Pitch were 1.0mm then 10 threads (at 1.0mm between threads) would equal 10mm.

These specifications should be all you need to purchase a replacement Thru Axle for virtually any frame or fork. If you have any questions about the material covered (or not covered) in this post please feel free to contact us for further information.